Yale Forklift Service Manual Speed Adjust

This is the Highly Detailed factory service repair manual for theYALE F818 GC-GLC080VX-BCS LIFT TRUCK, this Service Manual has detailed illustrations as well as step by step instructions,It is 100 percents complete and intact. They are specifically written for the do-it-yourself-er as well as the experienced mechanic.YALE F818 GC-GLC080VX-BCS LIFT TRUCK Service Repair Workshop Manual provides step-by-step instructions based on the complete dis-assembly of the machine. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly. YALE F818 GC-GLC080VX-BCS LIFT TRUCK Service Repair Manual.

This operation manual is the explanations that how to use 1-3tJ series forklift truck. Maintenance and management must read this manual thoroughly before. Gear box is two grades reduce speed gear, one grade straight gear and one. Position of brush have been adjusted; users mustn't unpack and adjust randomly. Read and Download Yale Forklift Service Manual Speed Adjust Free Ebooks in PDF format - JVC EVERIO MANUAL DOWNLOAD THE WISH HICCUPS IN A LIFE SOLUTION OF FUNDAMENTALS. Download and Read Yale Forklift Service Manual Speed Adjust Yale Forklift Service Manual Speed Adjust Following your need to always fulfil the inspiration to obtain everybody is now simple.

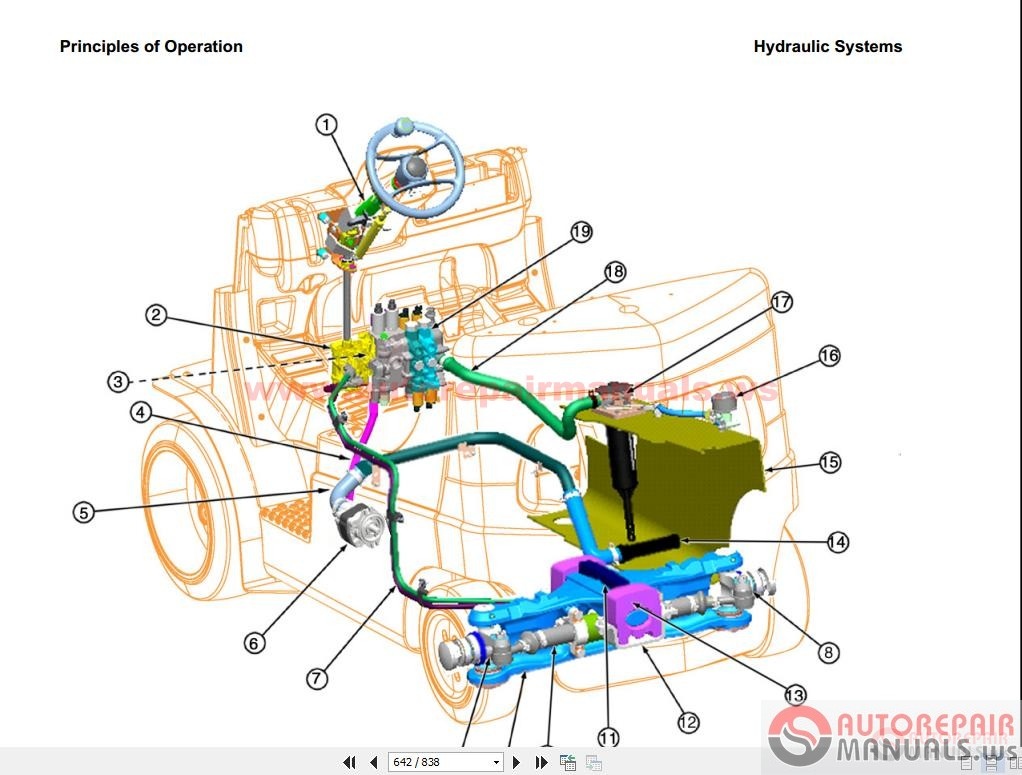

1. GC/GLC080VX & 080VX-BCS, GC/GLC100VX & 100VX-BCS, GC/GLC120VX & SVX & PRS (F818) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE FRAME. 5242 YRM 1243 05/14 GM 4.3L V-6 ENGINES. 5242 YRM 1251 05/14 COOLING SYSTEM. 5242 YRM 1123 03/13 LPG FUEL SYSTEM GM 4.3L ENGINE WITH PSI.

5500 YRM 1556 04/14 GASOLINE FUEL SYSTEM. 5500 YRM 1570 09/13 1 AND 2 SP PS TRANSMISSION REPAIR. 5500 YRM 1569 08/13 DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR. 5242 YRM 1246 12/13 DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR. 5500 YRM 1582 12/13 STEERING AXLE. 5242 YRM 1133 07/13 WET BRAKES - NMHG.

5500 YRM 1597 12/13 HYDRAULIC GEAR PUMP. 5242 YRM 1136 04/14 HYDRAULIC CLEANLINESS PROCEDURES. 5500 YRM 1620 12/14 MAIN CONTROL VALVE. 5242 YRM 1137 04/14 CYLINDER REPAIR (MAST S/N A551, A555, A559, A661, A662, A663, A66, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND E564). 5242 YRM 1139 02/14 HIGH VOLTAGE SWITCH (HVS) IGNITION. 5242 YRM 1097 05/14 WIRE HARNESS REPAIR.

5242 YRM 1128 12/14 USER INTERFACE. 5242 YRM 1130 12/14 USER INTERFACE. 5242 YRM 1131 12/14 ELECTRICAL SYSTEM. 5242 YRM 1142 04/14 MAST REPAIRS (S/N A513, A514, A613, A614, A702, A703, A704, A705, A706, A707, A751, A752, B513, B514, B586, B587, B588, B589, B590, B591, B749, B750, B751, B752, B753, B754). 5242 YRM 1250 02/14 METRIC AND INCH (SAE) FASTENERS. 5241 YRM 0231 10/13 CALIBRATION PROCEDURES.

Yale Forklift Manual

5242 YRM 1134 12/14 DIAGRAMS AND SCHEMATICS. 5500 YRM 1585 04/14 PERIODIC MAINTENANCE. 5500 YRM 1598 04/14 CAPACITIES AND SPECIFICATIONS. 5500 YRM 1599 04/14 DIAGRAMS AND SCHEMATICS. 5500 YRM 1689 04/14 DIAGNOSTIC TROUBLESHOOTING MANUAL.

5242 YRM 1112 12/14 Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center. 9000 YRM 1112 ON CD PART NO. 550064306 (12/14).

SAFETY PRECAUTIONS MAINTENANCE AND REPAIR. The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the product. Updated technical service information may be available from your local authorized Yale® dealer. Service Manuals provide general guidelines for maintenance and service and are intended for use by trained and experienced technicians. Failure to properly maintain equipment or to follow instructions con- tained in the Service Manual could result in damage to the products, personal injury, property damage or death. When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

Do not lift heavy parts by hand, use a lifting mechanism. Wear safety glasses. DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks. Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

Keep the unit clean and the working area clean and orderly. Use the correct tools for the job. Keep the tools clean and in good condition. Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to re- move parts.

Machinery Manuals| Parts Lists| Maintenance Manual| Service Instructions| Schematics SMW SpaceSaver 2000, Magazine Bar Feed, Operations and. Jun 20, 2013 - If you are searched for the ebook Smw 2000 space saver manual in pdf form, then you have come on to faithful site. We presented utter. Industrial Machinery Manuals Is Proud To Offer 1 Quality Bound Copy Of A: SMW SpaceSaver, 2000, Magazine Bar Feed, Installation Operations and. Smw spacesaver 2000 bar feeder parts.

Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. Be sure to follow the WARNING and CAUTION notes in the instructions. Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area.

Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this man- ual: WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage. On the lift truck, the WARNING symbol and word are on orange back- ground. The CAUTION symbol and word are on yellow background.

Yale Forklift Service Manual

©2014 Yale Materials Handling Corp. TABLE OF CONTENTS General.1 Hydraulic Gear Pump Assembly.

Yale Forklift Service Manual Pdf

1 Variable Displacement Pump Assembly. 2 Single Gear Pump Assembly Repair.

4 Remove. 4 Disassemble.12 Clean. 14 Inspect.14 Assemble.14 Install. 14 Tandem Gear Pump Assembly.20 Remove. 20 Disassemble.22 Clean.

24 Inspect.24 Assemble.24 Install. 25 Gear Pump Specifications. 26 Variable Displacement Pump Repair.31 Remove. 31 Disassemble.41 Clean. 45 Inspect.45 Assemble.46 Install. 46 Variable Displacement Pump Checks and Adjustments.51 Margin Pressure Check.51 Flow Compensator Adjustment.

52 Pressure Compensator Adjustment.52 Variable Displacement Pump Specifications. 54 Torque Specifications. 55 Hydraulic Gear Pump. 55 Variable Displacement Pump.